High-End ODM & OEM Custom

Eyewear and Sunglasses Manufacturer

for Premium Brands - Since 2003

Helping premium brands build standout eyewear — Reliably, at scale.

Yeetian – Your Strategic Partner in China

for Premium Custom Eyewear

From Design To Manufacturing

Faster to market: rapid sampling and on‑time delivery.

Lower risk: stable quality, compliant materials, clear QC reports.

Better margins: optimized costs without compromising premium finish.

In today’s uncertain global economy, every brand and buyer is asking the same question: how to get more value for a smaller budget? When “cutting costs and increasing efficiency” is mandatory, compromising on quality seems like an easy way out.

We firmly believe there is a better solution—High Quality ≠ High Price. This is not just a slogan; it is the founding principle and the answer we provide, rooted in our operations in Shenzhen’s eyewear manufacturing industry.

Breaking the Rule:

The “Craftsmanship” Behind Cost-Effectiveness

The old saying “you get what you pay for” holds truth, but it’s not unbreakable. Price limitations often stem from inefficiency and unnecessary middle costs. We, however, choose to fulfill our commitment to quality differently:

We are “meticulous” where you can't see:

We are obsessed with material selection, the number of hinge movements, and the smoothness of weld points. This “meticulousness” isn’t about piling on costs; it’s about precise control based on deep experience, ensuring every cent is spent where it enhances product longevity and wearing comfort.

MIDO 2026

Both No: Padiglione 5-A48

We are “nit-picky” where you can see:

Our manufacturing heritage in Shenzhen means we adhere to more international QC standards and stricter craftsmanship requirements. We dare to compare details and finishing with our peers in Wenzhou and DanYang—at the same price point, what you receive is tangibly, visibly superior quality.

Premium Service: Extending “Craftsmanship” to the Entire Workflow

True value lies not only in the product itself but in the entire experience of owning it. We integrate "craftsmanship" into our service to achieve maximum cost reduction and efficiency enhancement for you.

Design

We are not just manufacturers; we are your creative partners. We offer a vast library of existing designs and support deep customization, refining with you to make every frame an embodiment of your brand's personality.

Photography

We know professional product photography is costly. Therefore, we include professional-grade product photography as a standard service. From white-background to styled scene shots, we provide you with "ready-to-sell"marketing ammunition, saving you the high cost of photoshoots. [For custom orders of 1500 pieces and more]

One-Stop Brand Empowerment

SolutionA comprehensive solution that unifies design, manufacturing, and marketing assets. We don't just build products; we build the foundational assets your brand needs to launch and scale effectively in the global market.

Free Packaging

This is our solemn commitment to "premium service". You just provide the packaging design, and we handle the packaging of all products for free. We understand that overseas labor costs are high, and hand-packaging thousands of frames is time-consuming and expensive. Now, we handle this final step for you absolutely free. Products leave our production line ready to be shipped directly to your warehouse or market in perfect "retail-ready" condition, saving you one last significant expense. [For custom orders of 1500 pieces and more]

Our Promise: Let Your Budget Carry Bigger Dreams

Ultimately, “High Quality ≠ High Price” is a capability and a gesture of sincerity.

It means you don’t have to choose painfully between quality and cost. You can reinvest the budget you save—from product cost, photography, and packaging labor—into brand building and marketing initiatives with more direct returns.

Choosing us means not selecting a simple supplier, but a strategic partner dedicated to extreme cost-effectiveness through craftsmanship.

We promise to use Shenzhen’s refined quality and one-stop, hassle-free service to maximize the value of every cent in your budget, helping you navigate this era with stability.

Advanced Manufacturing Process

Precision Manufacturing Eyewear:

Sunglasses and Optical Glasses

Faster launches, consistent quality, and precise color‑matching. We engineer custom sunglasses and optical frames with zero-defect mindset.

Eyewear

Frame Material

In order to establish a clear brand identity, ensure product quality, and meet your target market demands, you should understand the right frame material for your brands, target audience preferences, material characteristics, and cost-effectiveness vs. performance.

Acetate Eyewear

Timeless Pilot

- Premium appearance

- Glossy finish

- Rich colors

- Durable & lightweight

- Adjustable fit

- Hand polished

Metal Eyewear

Durable Elegance

- Fashionable Appeal

- Stable Construction

- Adjustable Pads

- Anti-Corrosion

- Elegant Finish

- Custom Fit

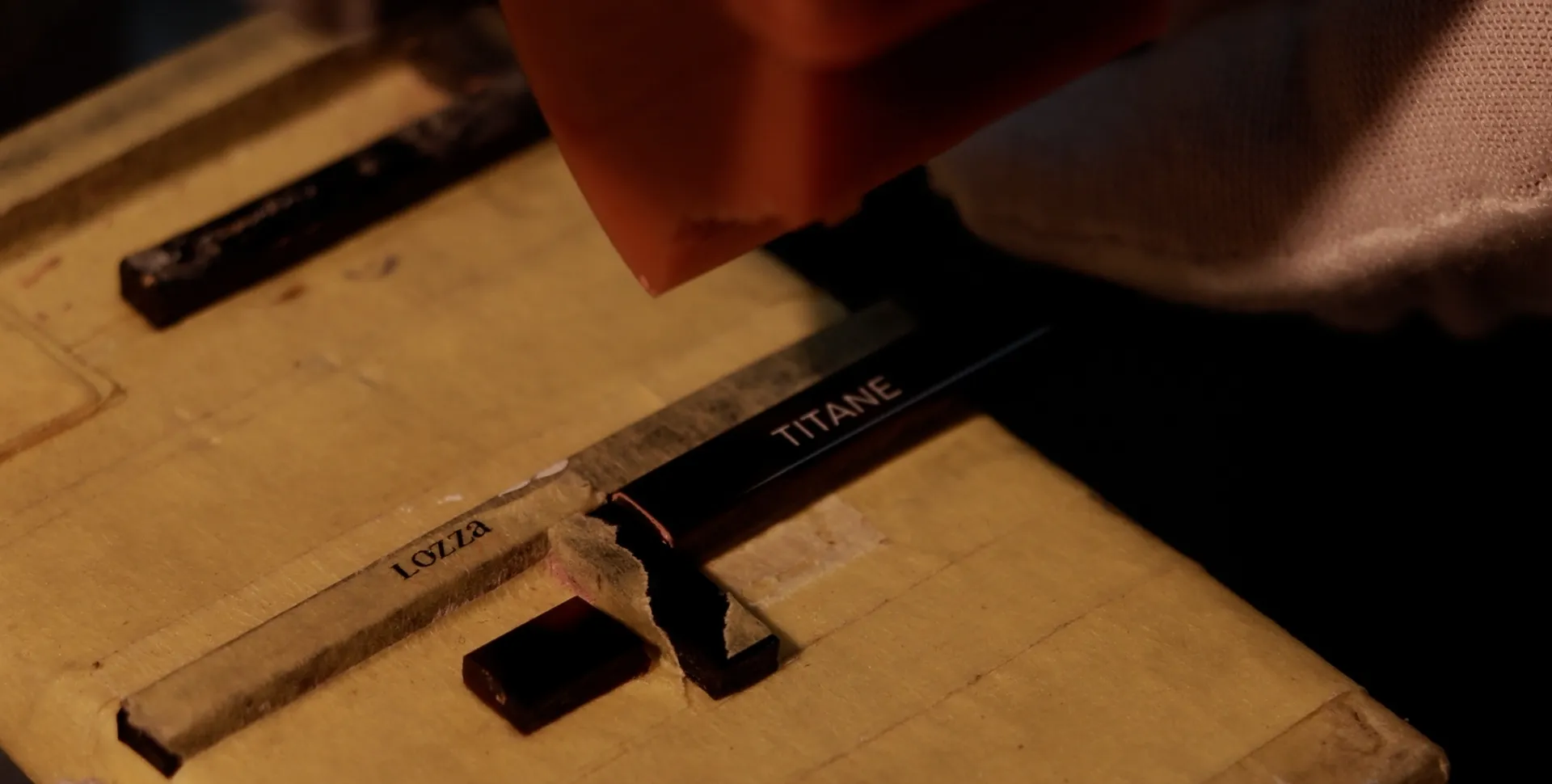

Titanium Eyewear

Lightweight

- Premium Aesthetic

- Durable Stability

- Lightweight

- Corrosion Free

- Hypoallergenic

- Modern Look

Stainless Steel Eyewear

Anti-Corrosion

- Fashionable Appeal

- Stable Build

- Adjustable Pads

- Rim Versatility

- Cost Effective

- Flexible Design

Nickel Silver Eyewear

Bold Molded

- Fashionable Appeal

- Stable Construction

- Rigid Structure

- Durable Quality

- Elegant Finish

- Custom Fit

Carbon Fiber Eyewear

Ultra-Light

- High Strength

- High Tech Look

- Premium Quality

- Handcrafted

- Unique Texture

- High Margins

Nylon Eyewear

Outdoor

- Durable Build

- Impact Resistance

- Lightweight

- Heat Resistance

- Outdoor Ready

- Various Colors

TR90 Eyewear

Memory Shape

- High Flexibility

- Impact Resistance

- Memory Shape

- Chemical Resist

- Skin-Friendly

- Affordable

Plastic Eyewear

Affordable

- Lightweight

- Affordable Cost

- Injection Molded

- Ready-Stock

- Low MOQ

- Smooth Finish

Wood Eyewear

Organic

- Natural Wood Grain

- Handcrafted Build

- Eco-Friendly

- Unique Texture

- Lightweight Feel

- Sustainable Choice

Buffalo Horn Eyewear

Luxury

- 100% Natural Horn

- Hypoallergenic

- Unique Patterns

- Ultra Premium

- Warm to Touch

- Skin Friendly

Bio-Acetate Eyewear

Sustainable

- Plant-based Material

- Biodegradable

- Eco-Friendly

- Non-Toxic

- Renewable Source

- Modern Aesthetic

Eyewear

Frame Shape

Choose shapes that sell and scale. Pick core classic silhouettes (Aviator, Wayfarer, Round, Rectangular, Square) plus a few seasonal trend pieces (Geometric, Hexagonal, Polygonal). Classics reduce tooling risk and speed production; trend shapes add margin and differentiation.

Aviator Eyewear

Teardrop Lenses

- Teardrop lenses

- Thin metal frame

- Double bridge

- Wide field view

- Lightweight fit

- Timeless classic

Wayfarer Eyewear

Squarish Front

- Trapezoid front

- Thick acetate frame

- Distinctive browline

- Sturdy temples

- Versatile styling

- Iconic look

Round Eyewear

Circular Lenses

- Circular lenses

- Soft edges

- Retro aesthetic

- Lightweight frames

- Gentle fit

- Suits square faces

Rectangular Eyewear

Wide Horizontal

- Horizontal lenses

- Straight top/bottom

- Clean modern look

- Broad visual field

- Professional styling

- Sharp corners

Square Eyewear

Equal Proportions

- Strong angular lines

- Bold silhouette

- Suits round faces

- High visual definition

- Thick frames common

- Statement piece

Cat-eye Eyewear

Upswept Corners

- Upswept outer corners

- Feminine shape

- Accentuated brow

- Vintage-inspired

- Flattering lift

- Fashion-forward

Butterfly Eyewear

Winged Upper

- Wide winged upper

- Oversized silhouette

- Dramatic look

- Soft lower edges

- Enhances cheekbones

- Fashion-focused

Panto Eyewear

Rounded Top

- Rounded top edge

- Flattened brow

- Vintage/retro feel

- Modest lens height

- Narrow nose fit

- Unisex appeal

Oval Eyewear

Soft Ellipse

- Elongated circle

- Soft curves

- Balanced proportion

- Timeless simplicity

- Smooth bridge

- Lightweight options

Geometric Eyewear

Multi-Sided

- Unconventional angles

- Fashion-forward

- Bold statement

- Multi-sided shape

- High customization

- Trend-driven appeal

Polygonal Eyewear

Angular

- Multi-angled shape

- Edgy aesthetic

- Strong geometric lines

- High-fashion use

- Customizable facets

- Statement accessory

D Eyewear

Flat-Top Curve

- Flat straight top

- Curved lower edge

- Strong silhouette

- Retro-meets-modern

- Good forehead coverage

- Bold top line

Rimless Eyewear

No Frame Rims

- No surrounding rims

- Minimalist look

- Lightweight wear

- Bare lens aesthetic

- Low visual weight

- Custom lens shapes

Semi-rimless

Top-Frame Only

- Top-frame only

- Open lower lens

- Lightweight feel

- Sporty to dressy

- Clear lower view

- Slim upper rim

Browline Eyewear

Heavy Upper Rim

- Heavy upper rim

- Thin lower rim

- Retro-professional

- Accentuated brows

- Mixed materials

- Mid-weight feel

Hexagonal Eyewear

Six-Sided Trend

- Six-sided structure

- Modern geometric

- Unique trend piece

- Soft angles

- Works on oval faces

- Contemporary vibe

Shape drives fit, comfort, and cost. It affects lens height, bridge fit, temple length, weight distribution, and QC tolerance. Standardize fit specs across similar shapes and match shapes to materials (acetate for bold color, metal for slim profiles, TR90/nylon for lightweight). This keeps quality consistent, lowers returns, and simplifies inventory.

Eyewear

Frame Color

Elevate your brand’s luxury appeal with carefully curated frame colors. Select from timeless, sophisticated hues (black, white, brown, tortoise, gray) that form the backbone of high-end collections, offering versatility and a refined aesthetic. Introduce captivating statement colors or unique effects to add exclusivity.

Black Eyewear

Deep Contrast

- Deep contrast

- Cool neutrality

- High versatility

- UV protection

- Fade resistant

White Eyewear

Clean Minimal

- Versatile pairing

- Stain resistance

- Clean contrast

- Timeless appeal

- High visibility

Brown Eyewear

Warm Earth

- Tonos cálidos

- Profundidad terrosa

- Saturación rica

- Complemento natural

- Calidez atemporal

Gray Eyewear

Neutral Balance

- Neutral balance

- High versatility

- Timeless neutrality

- Subdued elegance

- Reflective control

Tortoise Eyewear

Patterned Warmth

- Patterned warmth

- Multi-tonal depth

- Classic appeal

- Timeless versatility

- Versatile pairing

Transparent Eyewear

Barely There

- Barely there

- Colorless neutrality

- Low visual weight

- Versatile pairing

- Lightweight look

Matte Eyewear

Low Sheen

- Low sheen

- Subdued reflection

- Durable finish

- Fingerprint resistant

- Modern understatement

Solid Eyewear

Consistent Hue

- Consistent hue

- Even coverage

- Colorfast finish

- Clean edges

- Bold statement

Neon Eyewear

Vivid Pop

- High visibility

- Vivid saturation

- Bold statement

- Attention grabbing

- Fade resistant

Patterns Eyewear

Layered Grain

- Layered grain

- Patterned warmth

- Durable resin

- Rich translucence

- Color variation

Silver Eyewear

Cool Metallic

- Cool metallic

- Durable plating

- Corrosion resistance

- Modern sleekness

- Reflective sheen

Green Eyewear

Natural Harmony

- Earthy hue

- Timeless freshness

- Depth variation

- Natural harmony

- Skin complement

Red Eyewear

Bold Presence

- Bold presence

- High saturation

- Eye-catching

- Statement color

- Colorfast finish

Masterfully handle color to define your brand's identity and ensure product excellence. Our expertise extends to matching sophisticated color palettes with the finest materials—whether it’s the rich depth of a bold color on premium acetate, the sleek finish of a sophisticated metal, or the nuanced transparency of a specialized finish. This precision engineering ensures consistent quality, allows for sophisticated design storytelling, and positions your eyewear as a mark of discerning style and superior craftsmanship.

Eyewear

By Audience & Style

Segment your wholesale offerings by audience and lifestyle to address varied consumer needs efficiently. Men’s frames emphasize secure fits with wider bridges and reinforced hinges for durability, while women’s designs focus on flattering silhouettes, lightweight materials, and adjustable nosepads for comfort and style. Unisex styles provide balanced proportions and gender-neutral finishes to appeal to a broad demographic.

Men Eyewear

Masculine Classics

- Secure fit

- Heavier construction

- Reinforced hinges

- Wider bridges

- Substantial temples

- Matte / metal finishes

Women Eyewear

Feminine Silhouettes

- Flattering fit

- Lightweight construction

- Adjustable nosepads

- Slim temples

- Multiple widths

- Decorative details

Unisex Eyewear

Neutral Fit

- Universal proportions

- Balanced bridges

- Medium temple width

- Classic silhouettes

- Gender‑neutral finishes

- Broad size range

Casual Eyewear

Everyday Comfort

- Easy fit

- Lightweight build

- Flexible temples

- Neutral finishes

- Low visual weight

- Consistent sizing

Outdoor Eyewear

Trail & Travel

- Secure all‑day fit

- Durable construction

- Reinforced hinges

- Ventilated frames

- All‑weather finishes

- Adjustable bridges

Driving Eyewear

Safe Comfort

- Low temple profile

- Stable bridge fit

- Balanced weight

- Narrow temple ends

- Comfortable pressure

- Secure hold

Classic Eyewear

Minimalist Timeless

- Thin rims

- Low visual weight

- Clean lines

- Neutral finishes

- Slim temples

- Timeless proportions

Fashion Eyewear

Fashion Forward

- Bold silhouettes

- Oversized fronts

- Distinct patterns

- Thick acetate fronts

- Statement temples

- High‑gloss finishes

Business Eyewear

Corporate Classics

- Slim profiles

- Sleek metal options

- Neutral tones

- Moderate weight

- Subtle contours

- Consistent sizing

Luxury Eyewear

Heritage Luxury

- Hand‑polished acetate

- Premium metals

- Intricate detailing

- Heavier premium feel

- Fine hinges

- Limited batches

Sports Eyewear

Athletic Performance

- Patterned warmth

- Multi-tonal depth

- Classic appeal

- Timeless versatility

- Versatile pairing

Marine Eyewear

Marine Ready

- Corrosion‑proof hardware

- Salt‑resistant plating

- Quick‑dry finishes

- Non‑slip nosepads

- Reinforced hinges

- Floatable options

This segmentation guides frame selection by linking features to specific use cases. Casual frames with easy fit and neutral finishes cater to everyday versatility, business styles with slim profiles and sleek metals suit professional environments, and driving eyewear with stable bridge fits and secure holds enhance comfort during travel. Marine-ready options with corrosion-resistant materials and non-slip grips address niche activities, enabling you to confidently curate collections that resonate with targeted lifestyles and reduce fit-related issues.

Eyewear

Frame By Treatments

The most versatile finishes—Matte, Glossy, and Metallic—deliver universal appeal through practical benefits like glare reduction, deep color richness, and premium shine. Expanding into expressive finishes like Patterned, Transparent, and Brushed Metal enables distinctive styling with unique textures and lightweight appeal, ideal for customers seeking individuality without sacrificing comfort.

Textured and tactile options such as Aged Metal, Wood Grain, and Hand-Polish convey artisanal quality and exclusivity, resonating with consumers who value authenticity and luxury detailing. By strategically balancing staple and statement treatments, you can effectively address diverse consumer preferences while optimizing your wholesale assortment for both volume and margin.

Custom Manufacturing for Your Brand

Bespoke luxury frames crafted with precision and speed

Premium Material Selection

We source only the finest premium acetate and other high-grade materials. Each batch is carefully inspected to ensure consistent color, density, and structural integrity so every frame starts with a superior foundation for durability and luxury finish.

Tumbling & Surface Finishing

After the frame fronts and temples are formed, they undergo a multi-stage five-day tumbling process. Gentle, controlled abrasion with small oiled wooden pieces progressively smooths and polishes surfaces. Different stages use progressively finer abrasives; pieces may re-enter earlier stages to achieve matte or semi-matte textures.

Precision Hand Filing

Skilled craftsmen thoroughly inspect tumbled parts and remove any remaining imperfections by hand. Using precise filing techniques, they refine edges, contours, and surface details to ensure the frame matches the intended design and meets exacting aesthetic and fit standards.

Signature Branding & Decoration

Our artisans apply logos and decorative elements using techniques chosen to best suit the material and design—printing, hot-stamping, engraving, crystal paste, metal paste, 3D metal, and more. Each mark is placed with care to be both durable and visually flawless.

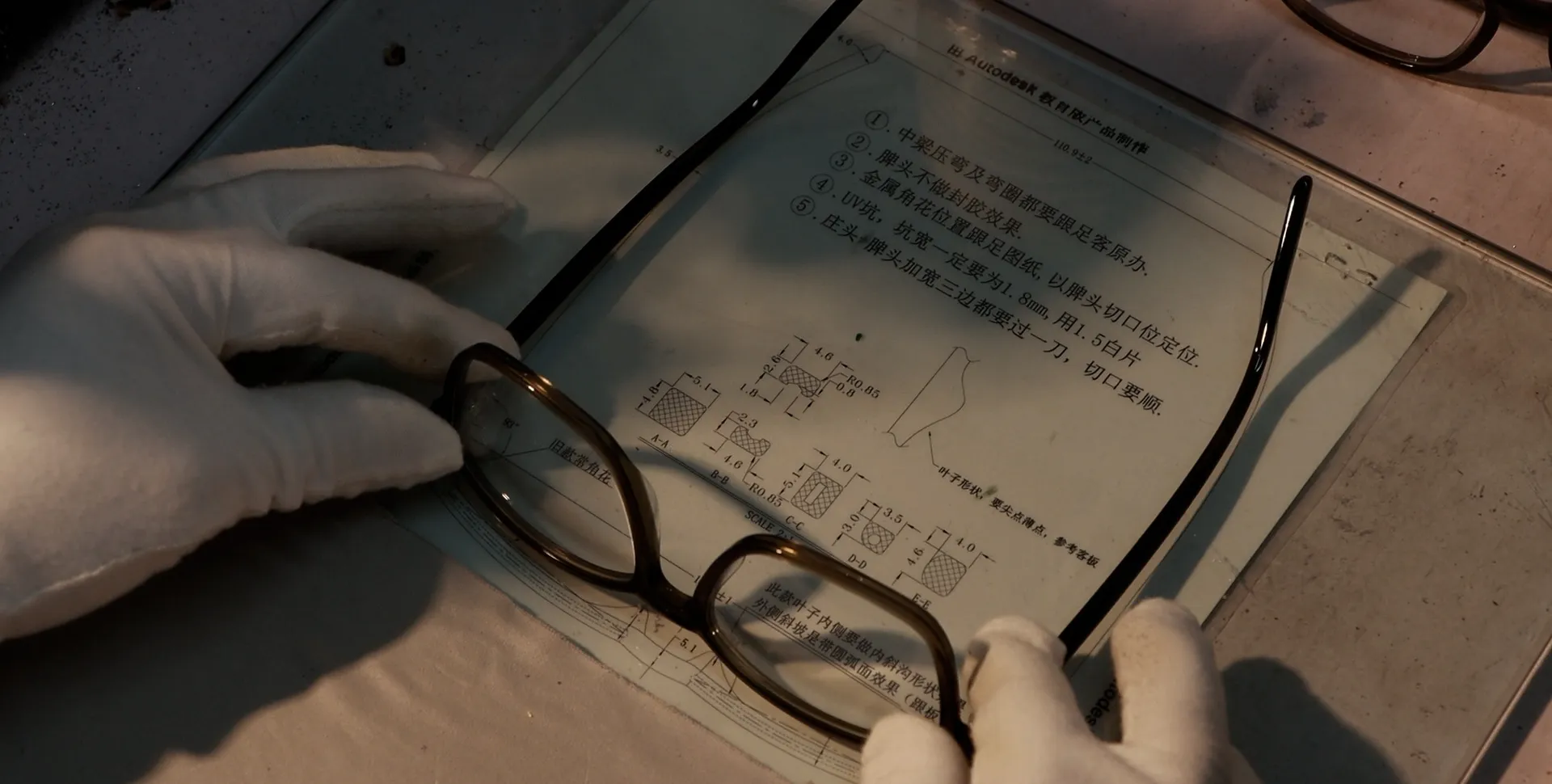

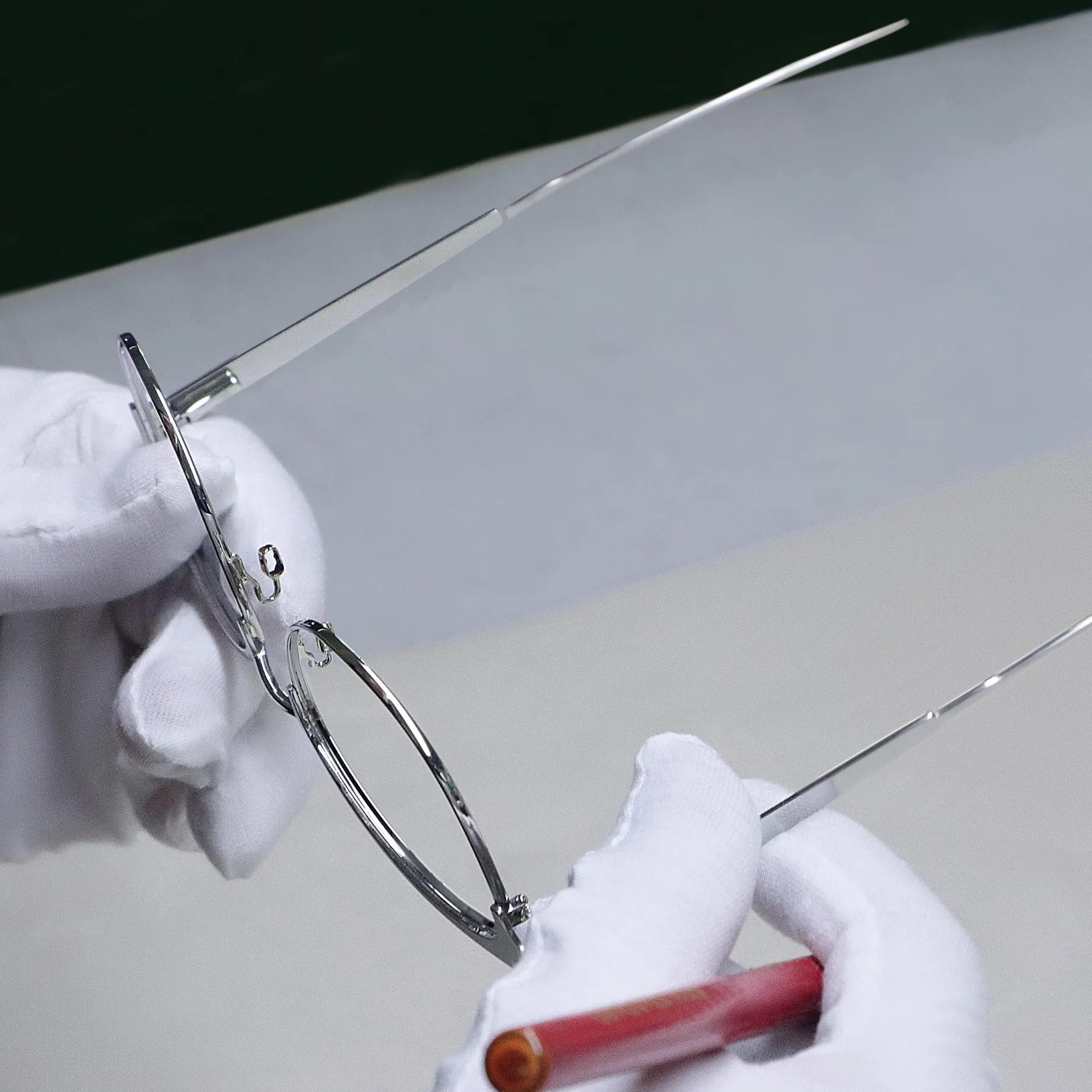

Assembly & Fine Polishing

Experienced technicians assemble frame components and perform meticulous hand polishing similar to fine jewelry finishing. Components are adjusted and measured with micrometer-level tolerances against the original technical drawings to ensure optimal fit, balance, and finish.

Final Quality Inspection

Before shipment every frame undergoes a comprehensive quality check. Craftsmen perform dimensional inspections, visual and functional tests to confirm structural integrity, finish consistency, branding quality, and overall workmanship so only products meeting our highest standards are delivered.

Customization &

Manufacturing Process

Turn your design into production-ready frames. We execute the full cycle—from CAD & prototyping to multi-layer acetate lamination and precision finishing—with low MOQs and strictly managed lead times.

- 01 Prototyping & R&D

- 02 Mould & Tooling

- 03 Acetate Processing

- 04 Injection Molding

- 05 CNC Metalwork

- 06 Assembly Processes

- 07 Lens Cutting

- 08 Surface Finishing

- 09 Quality Control

- 10 Flexible Lines

- 11 Mass Production

- 12 Special Add-ons

Customization Levels —

From Catalog Changes to Bespoke Collection

Eyewear Customization from minor color tweaks to full new tooling. Scalable solutions designed for rapid market entry or exclusive brand positioning.

Frame Cutting

Frame Polishing

Frame Shaping

Frame Inspection

Catalog SKU

No Tooling Required

Ideal for quick market entry. Select from our existing library with minor color changes and private-label branding.

Semi-Custom

Minor Tooling

Small adjustments to geometry, customized hardware details, or specific material combinations.

Full Custom

New Mould Creation

Total creative control. Brand-new frame geometry, bespoke hardware, and exclusive material recipes.

Bespoke

Collaboration

High-end limited runs, artisan finishes, Japanese acetate, and luxury custom packaging.

What is a "minor colour change"?

Uses existing tooling but applies new color recipes or acetate sheets. No new mould fees are incurred, and MOQs are typically lower.

Do you charge tooling for semi-custom?

Small jig or tooling adjustments may incur modest fees (e.g., custom lens shape within existing frame), whereas full new moulds require a standard tooling quote.

Can you run a pilot batch?

Yes. We offer small-batch pilot runs for market validation. Pricing and lead times for pilots depend on the customization level selected.

How are tooling costs amortized?

Tooling costs can be amortized across future production runs. We can propose schedule offsets or tooling fee rebates for consistent repeat orders.

Hardware & Components

We supply a full range of precision eyewear hardware and components — sourced or manufactured to exact OEM standards for durability and performance.

01 Key Component Library

Hinges

Standard screw hinge, spring hinge, hidden hinge, screwless designs.

Screws & Fixings

Stainless steel micro screws, rivets and rivet-less assembly options.

Metal Cores

Steel, stainless or titanium cores for temples and acetate fronts.

Nose Pads & Arms

Silicone pads, adjustable metal pad arms and acetate pad options.

Temple Tips

Acetate tips, rubberized tips, custom-shaped endpieces.

Badges & Logos

Metal badges, laser-engraving, and inlaid emblems.

Small Parts:

Spacers, washers, adhesive types, and spare hardware kits.

02 Hinge Mechanisms

Standard Screw

10K CYCLESDurable, serviceable, classic 3/5/7 barrel design.

Spring Hinge

FLEX FITFlexible fit; recommended for premium consumer wear.

Hidden Hinge

MINIMALClean aesthetic; requires precise drilling & assembly.

Screwless / Snap-fit

MODERNMinimalist look; lower serviceability.

Materials & Finishes

Ultra-light, corrosion-resistant, premium price.

Cost-effective, durable and corrosion-resistant.

Traditional eyewear alloy with good formability.

PVD, electroplating (gold / rose / black), passivation.

Quality & Testing

All hardware undergoes incoming inspection and batch testing: salt-spray corrosion, hinge cycle fatigue tests, torque/tension checks, plating adhesion and dimensional tolerance verification. Test reports available on request.

Spare Parts & Service

We offer spare parts kits and repair support for volume clients. For commissioned projects we can reserve spare components and provide replacement lead times in the contract.

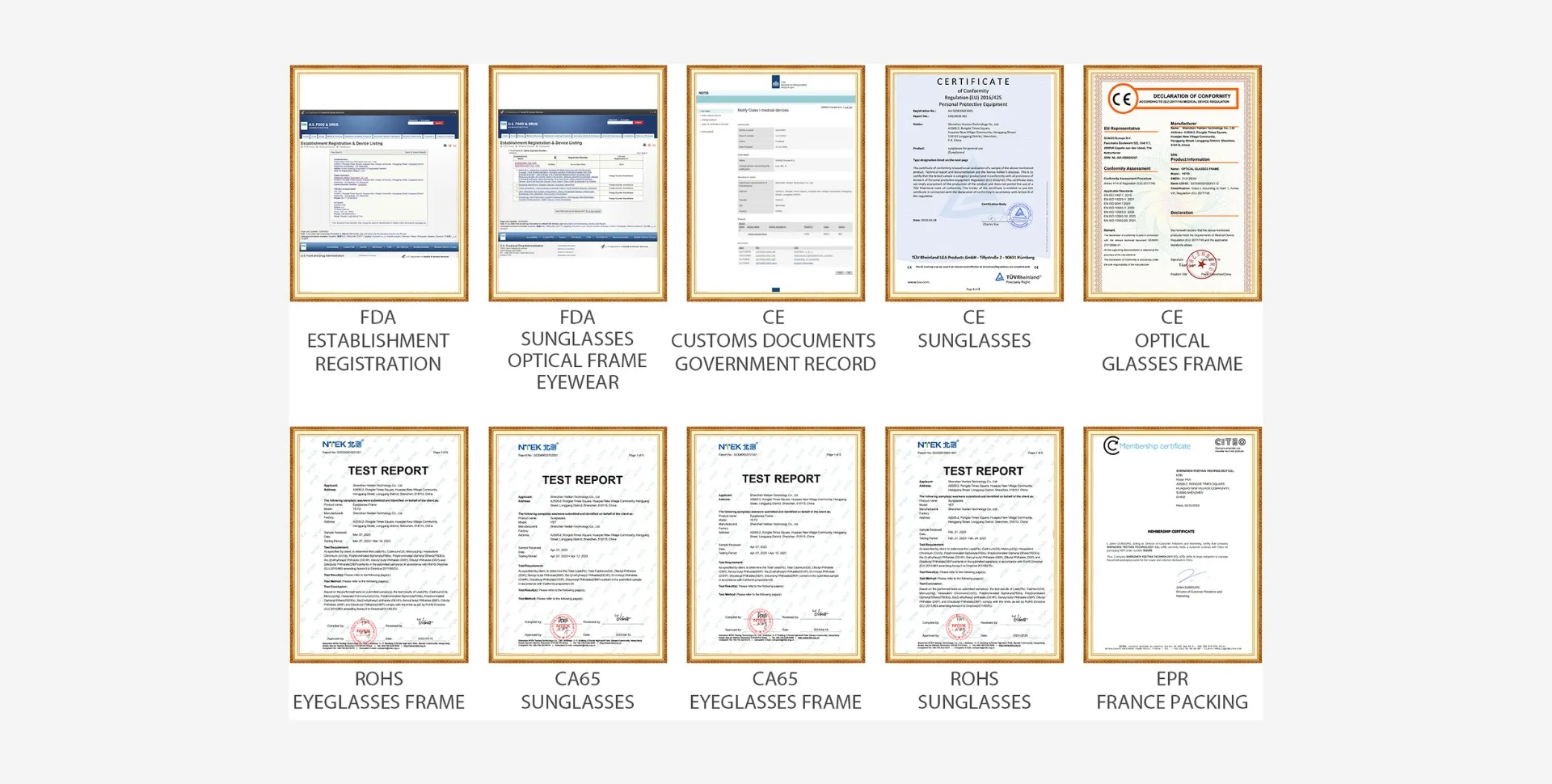

Certifications & Compliance

We adhere to international safety and chemical regulations — REACH, CE, ISO and third-party testing available on request.

Documentation Speed

Audit Efficiency

Our frames are manufactured under strict quality control and material compliance programs. We provide CE testing, FDA and REACH documentation for sunglasses upon request, and third‑party laboratory reports (SGS/Intertek).

Also supporting CPSIA/EN standards for children's lines.

Compliance FAQ

Ask a specific question →Can you provide REACH test reports for acetate materials?

Yes — we can provide REACH compliance documentation and third-party test reports upon request.

Do you provide material safety data sheets (MSDS)?

Yes — we supply MSDS and material declarations for coatings, adhesives and plating chemicals on request to support your compliance reviews and lab testing.

Do you have CE test reports for sunglasses?

CE testing (EN ISO 12312) is available on request; tests are performed by accredited labs and reports can be shared with serious buyers.

Can you arrange third‑party lab testing?

Yes — we can coordinate accredited third‑party testing (SGS/Intertek/TÜV) for specified batches or pre‑shipment samples and deliver full lab reports to buyers.

Are your factories audited for social compliance?

Yes — we hold BSCI / SMETA audit records and can share audit summaries with qualified buyers under NDA.

How do you manage certificate validity for repeat orders?

We track certificate expiry and batch test records; for reorders we verify material lots and, if required by the buyer or standard, arrange re‑testing.

Packaging & Labelling

We offer retail-ready and bulk packaging solutions tailored to your brand — from premium PU cases and windowed retail boxes to sustainable mailer options and full retail POS kits.

Color GiftBox

Leather PU

Soft Pouch

Display Kits

Paperboard

EVA Inserts

Color Print

Hang Tags

Barcode

Bulk Cartons

Quality Management & Protocols

Quality Management System

We operate under a documented Quality Management System aligned with ISO 9001 principles and maintain factory audit records (BSCI/SMETA).

Prototype & PPS Approval

We produce prototypes (3D printed or hand‑built) for design validation and provide Pre‑Production Samples (PPS) for buyer approval.

Custom Materials

We support custom material requests including acetate, premium Italian/Japanese acetate, bio‑acetate, TR90, nylon, and titanium.

Incoming Material (IQC)

All incoming materials are inspected against specs. We verify supplier certificates and perform dimensional checks for cores and hardware.

Final Inspection (FQC)

Final inspections follow AQL sampling plans. Each shipment includes an FQC report covering visual, dimensional and functional checks.

Third‑Party Testing

We coordinate third‑party testing (SGS/Intertek/TÜV) for UV protection, impact resistance, and chemical compliance (REACH/CPSIA).

In‑process Controls (IPQC)

IPQC checks performed at cutting, thermoforming, and hinge installation stages using standardized checklists and go/no‑go gauges.

Corrective Actions (CAPA)

Non‑conformities trigger a formal CAPA process. KPI trends (defect rates) are reviewed monthly and feed into training.

Batch Traceability

Full traceability from raw material lot to finished goods. Production records and retention samples kept for minimum 2 years.

End‑to‑End Quality Assurance

Full‑line quality assurance from incoming material checks to final shipment — certified testing, inline controls, and batch traceability to ensure consistent, compliant delivery for every order.

Raw Material Cutting

Shape Nose Bridge

Adding Nose Pads

Engraving Frame

Engraving Temple

Insert Needle

Shape Nose Bridge

Install Hinges

Polishing

Cutting Lens

Premium Acetate, Metal &

Hybrid Frames

Yeetian Technology Co., Ltd. is a Shenzhen‑based OEM/ODM manufacturer specializing in premium acetate, metal and hybrid eyewear frames. With over 20 years of industry experience and a 5,500 m² factory capacity exceeding one million units annually, we offer end‑to‑end services from design and prototyping to moulding, finishing and logistics.

Certified to industry standards and committed to sustainability, we partner with global brands to deliver dependable quality, customizable solutions and transparent communication. From prototype to retail-ready shipment, we engineer certainty.

End-to-End Excellence

Shenzhen-based OEM/ODM manufacturer of premium acetate, metal and hybrid frames — design, prototyping, tooling and export-ready production for global brands. 20+ years of craftsmanship, scalable capacity and sustainable practices — from prototype to retail-ready shipment.

The Yeetian Standard

Our Mission

Improve the eyewear industry with exceptional design, caring service, innovation and circular‑economy practices.

Core Values

Quality, sustainability, team spirit and long‑term partnerships.

Capabilities

Full OEM/ODM: R&D, CAD/3D, moulding, multi‑layer acetate, CNC metalwork, lens assembly and packaging.

Signature Processes

Hand‑selected premium acetate, multi‑stage tumbling, meticulous filing, artisan polishing and strict multi‑stage inspection.

Business Development Team

Dedicated partners guiding you from concept to completion

Tian

"Decades of collaboration with renowned brands — I develop tailored collections."

Sunny

"I listen honestly and deliver fast, professional solutions to keep you moving."

Cassie

"Let’s find your perfect frames together. Bringing your vision to life."

Howard

"Dedicated support ensures a seamless process from purchase to delivery."

Jack

"100% perfect—full customization with consistent product quality."

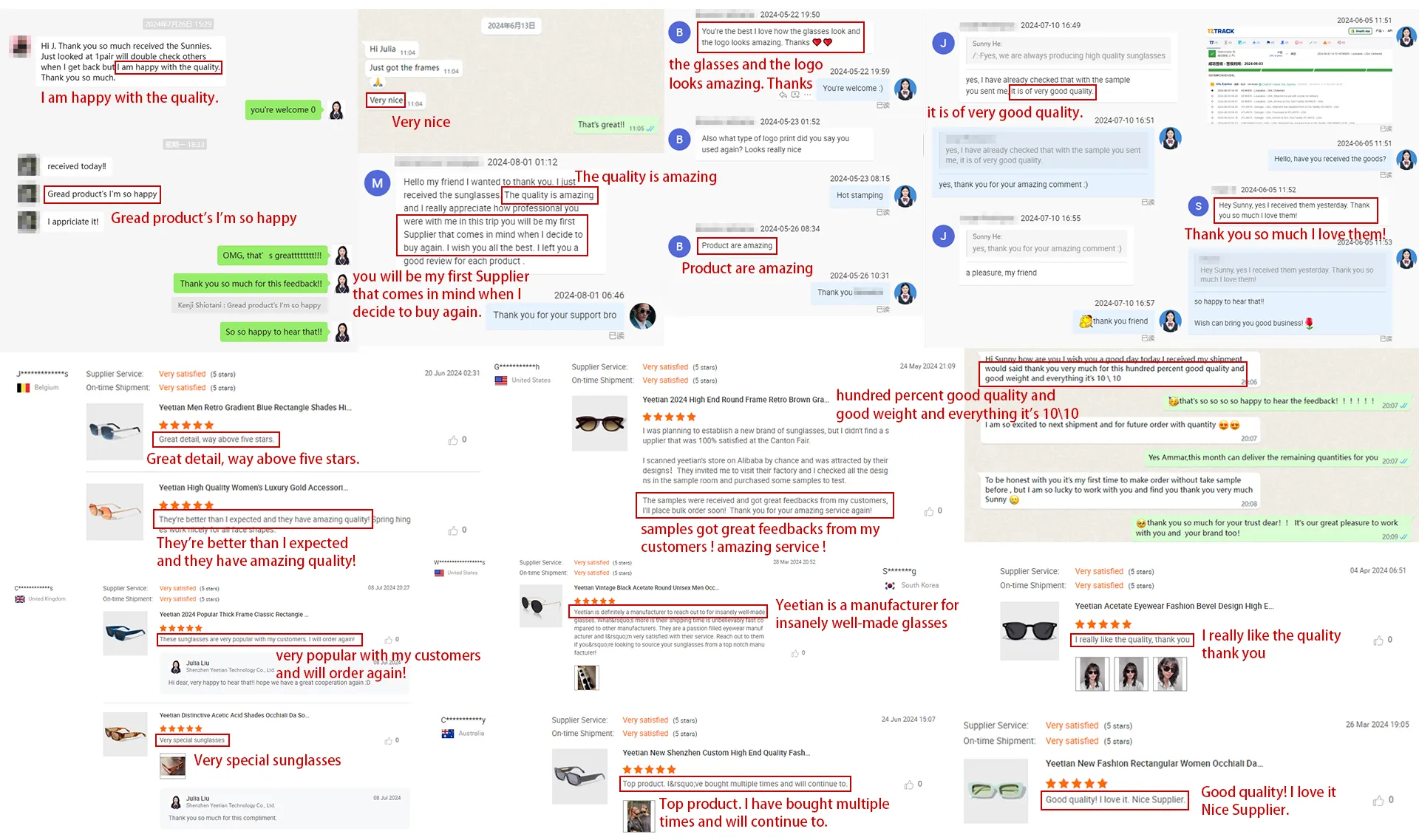

Trusted by Global Brands

Trusted by global brands and private labels — read verified testimonials and case highlights that demonstrate our manufacturing quality, on‑time delivery and OEM/ODM expertise.

"Yeetian delivered flawless colour matching and on‑time production for our seasonal sunglass drop. Their prototyping process and sample updates made the launch seamless."

Anna Lee

"Yeetian’s sustainability options and certified supply chain allowed us to label a recycled‑content eyewear line with confidence. Their audit docs simplified our compliance checks."

David Müller

"For our technical sports line we required TR90 performance frames and precision assembly. Yeetian handled materials sourcing, lens assembly and expedited shipping with excellent support."

Emily Wang

"Finding a factory that understands 'luxury weight' was a challenge until we found Yeetian. Their acetate milling and hand-polishing techniques gave our frames the substantial, premium feel our clients demand."

Lucas Dubois

"Transitioning our D2C brand's manufacturing to Yeetian was seamless. Their communication is clear, their lead times are reliable, and the consistent quality has significantly reduced our return rates."

Jessica Chen

Video Spotlights

Newest Ratings and Reviews

Start Your Private-Label

Million-Dollar Business.

Fully customize every detail of your eyewear—material, shape, color, and technical specs. Partner with a manufacturer that understands the nuances of luxury.

1501, Bldg. 2, Baiwangda Health Tech Park, Yuanshan St., Longgang Dist., Shenzhen, China