Your Trusted Sunglasses Manufacturer in China

We Deliver One Thing: Measurable Certainty

For sunglasses expert leaders like you, know that any production surprise directly threatens your go-to-market timeline, budget, and brand reputation. We transform your greatest manufacturing risks into a predictable system driven by data and disciplined processes. With us, you’re not just procuring eyewear—you’re securing complete control over your Return on Investment (ROI)

100% Transparent Communication

Your dedicated Project Manager ensures information reaches you proactively, not reactively. Through our project management system, you receive standardized weekly reports that include:

Progress Sync: Real-time status tracking across 9+ critical production milestones, allowing for immediate course correction when needed—so you see progress at every key step.

Risk Alerts: Advanced warnings for potential deviations, identified 72+ hours in advance and delivered with proposed solutions—preventing costly mid-production adjustments.

≥99.8% Quality Consistency

We replace vague assurances of “good quality” with traceable data. From IQC to OQC, all inspection reports are updated in real-time within our system, available for your on-demand review. This means:

Zero Batch-to-Batch Discrepancy: We guarantee the quality variance between the first and the one-hundredth production run remains below 0.01%, eliminating retailer rejections and consumer perception issues.

What You Approve Is What We Produce: Every detail confirmed at the sampling stage becomes a non-negotiable standard for mass production, maintaining the integrity of your design intent.

99.5% On-Time Delivery Rate

Your delivery date is the highest-priority directive in our ERP system, which is fully integrated with our production schedule. Every delivery represents a meticulously managed commitment.

Protecting Your Go-to-Market Schedule: We aim to have your shipment arrive at your warehouse 3 days ahead of schedule, safeguarding your launch timeline and seasonal placement windows.

Eliminating the Cost of Delays: In the past 12 months, we’ve had zero major at-fault shipment delays, saving our clients the significant opportunity costs associated with market timing failures.

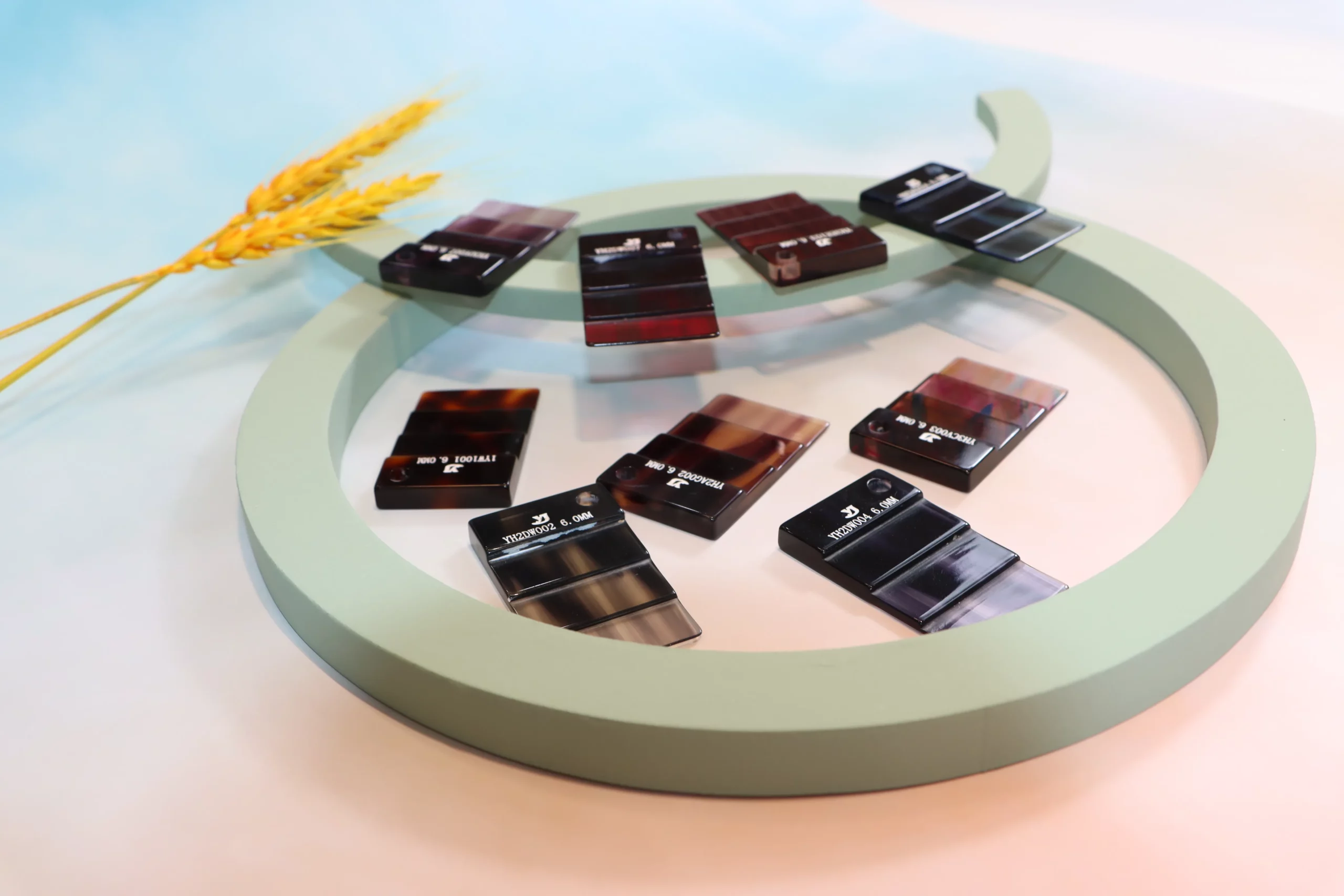

Custom Materials for Your Sunglasses Collection

Premium acetate, metal and hybrid frame materials for custom eyewear frames

Custom Frame Shapes for Your Sunglasses Collection

Classic to contemporary silhouettes — find the right frame shape for your sunglasses collection

Custom Color Range for Your Sunglasses Collection

Extensive acetate swatches, custom color matching and premium finishing options for your private-label collections

Custom Segments for Your Sunglasses Collection

Tailor by Audience and Use: Men, Women, Unisex, Casual, Fashion, Sport, Driving, Outdoor

Trust Is Not a Slogan; It’s an Auditable System

We believe your eyewear designs deserve execution backed by verifiable standards. That’s why we’ve built a comprehensive compliance infrastructure that transforms abstract promises into documented, auditable processes. Our framework has been certified by international authorities and validated through rigorous brand audits—giving you the operational certainty your business requires.

Auditable Global Compliance Framework

We’ve systematically implemented certifications covering both management systems and market access requirements across all major global markets. This eliminates compliance risks at the source and ensures your products face no regulatory barriers.

Quality Management System: Our ISO 9001:2015 certified operations maintain complete traceability for every production directive.

Global Market Access: All products meet CE (EN ISO 12312-1) and FDA standards, with verified compliance for chemical safety regulations including REACH and Proposition 65.

Corporate Social Responsibility: Full BSCI and SEDEX audit compliance safeguards your brand reputation through verified ethical supply chain practices.

Our Market-Vetted Track Record

The true measure of manufacturing expertise is consistency through complexity. Our performance history offers the most reliable prediction of your future success with us.

20+ Years of Industry Immersion: Over a decade of specialized eyewear manufacturing experience means we’ve already solved thousands of technical challenges similar to yours.

13+ Million Units Delivered: With millions of eyewear pieces successfully produced, we’ve demonstrated the capacity to maintain quality at scale across diverse product specifications.

Trusted by 15+ International Brands: Our engineering and production systems have been vetted through the stringent approval processes of leading global eyewear brands.

Absolute, Legally-Binding IP Protection

Your design intellectual property deserves uncompromising protection. Every partnership begins with legally-binding NDAs, reinforced by physical access controls and segregated digital servers that keep your proprietary designs secure throughout the development and production process.

Our Ultimate Confidence: A One-Year Official Warranty

We stand behind our manufacturing precision with a comprehensive one-year warranty covering all manufacturing defects. This warranty reflects our confidence in our systems, materials, and execution standards—and provides you with quantifiable risk reduction.

Your Core Challenge: The “Management Tax” on Supplier Errors

For a successful eyewear brand, a brilliant design is the beginning, not the end. The real challenge is transforming a design blueprint into tens of thousands of units, all flawlessly executed and delivered on time. The cost of the wrong manufacturing partner extends far beyond the invoice; it levies a “Management Tax” on your business in three distinct forms:

Opportunity Cost: Missed Market Window

Any weak link in the supply chain—from raw material shortages to scheduling errors—can result in significant delivery delays. In eyewear market, a 3-week delay can cause a key product to miss up to 40% of its quarterly sales forecast, forcing you to cede first-mover advantage to competitors while inventory problems compound. We prevent slips with secured materials, buffer capacity, and milestone tracking—so launches hit the window, not the delay.

Brand Cost: Erosion of Brand Equity

Customer complaints and returns stemming from manufacturing defects or batch-to-batch inconsistency slowly erode the brand trust you’ve invested heavily to build. Every sunglasses replacement and apology is an overdraft on your brand’s reputation, inflicting long-term damage that far exceeds the cost of a single order. Our rigorous quality control processes and consistent production standards protect your brand equity through every manufacturing cycle.

Management Cost: Leadership Focus

Your team should focus on brand strategy, marketing, and product innovation—not chasing deadlines, rechecking quality, or mediating supplier communications. These tasks can consume up to 20% of leadership bandwidth and reduce strategic capacity. We eliminate this drain through proactive engineering communication, documented process control, and consistent execution—so your team stays focused on growth initiatives rather than manufacturing oversight.

Our Philosophy: To Engineer Certainty, Not Just Eyewear

Seasoned eyewear leaders like you know the difference between factories that follow instructions and partners that prevent problems. While others view production as execution, we define it as proactive risk management. Your most valuable manufacturing work happens the moment we review your first design drawing—not on the assembly line. Our philosophy transforms manufacturing from an unpredictable risk into a calculable strategic asset for your brand through three core principles.

Eliminate Risk at the Source

The most effective cost and quality control is removing >80% of foreseeable manufacturing risks before you spend on tooling or materials. At the project kickoff, our engineers serve as your first critical users with a DFM² review (Design for Manufacturability & Marketability) to protect outcomes, not just intent.

Structural Risk Identification: Your temple design, when produced in this specific material, shows a fracture risk exceeding our internal safety standards after 3 years of simulated wear—we’ll recommend precise material adjustments to maintain your aesthetic while ensuring durability.

Cost Risk Optimization: While aesthetically compelling, your design’s mold complexity would increase tooling costs by approximately 30%. We can propose structural alternatives that preserve your design intent while reducing production complexity and lead times.

Process Risk Warning: This large-area, light-gradient spray finish has a statistical variance risk exceeding 5% in mass production. We’ll recommend process adjustments to ensure color consistency across all production runs, protecting your brand standards.

Optimize for Total Cost of Ownership (TCO)

We don’t discuss price—we engage in strategic dialogues about value. Our goal isn’t to be your cheapest option, but your best investment with the highest risk-adjusted return:

Where You Can Save: Adjusting the surface finish on this non-critical structural component from Grade A to Grade B will reduce unit costs by approximately 4% without compromising function or appearance—allowing you to reinvest in features your customers actually notice.

Where You Must Not Compromise: Our test data shows your alternative hinge supplier carries a 15% higher long-term failure risk. This translates directly to warranty claims and brand reputation damage—we recommend maintaining your specified supplier to protect customer satisfaction.

Engineer for the End-User Experience

We look beyond the blueprint to your customer’s experience two years after purchase—because that’s when your brand reputation is truly earned:

Mechanical Durability Validation: Hinges must pass 20,000-cycle endurance testing, simulating 5 years of daily use with torque degradation maintained within 0.1%—eliminating the risk of premature field failures. Our testing protocols simulate real-world wear to ensure your products maintain precision throughout their lifecycle.

Ergonomic Analysis: This design’s weight distribution creates excessive pressure on the nose bridge for over 25% of our reference user profiles. We can recommend subtle adjustments that maintain your aesthetic while improving comfort for a broader customer base.

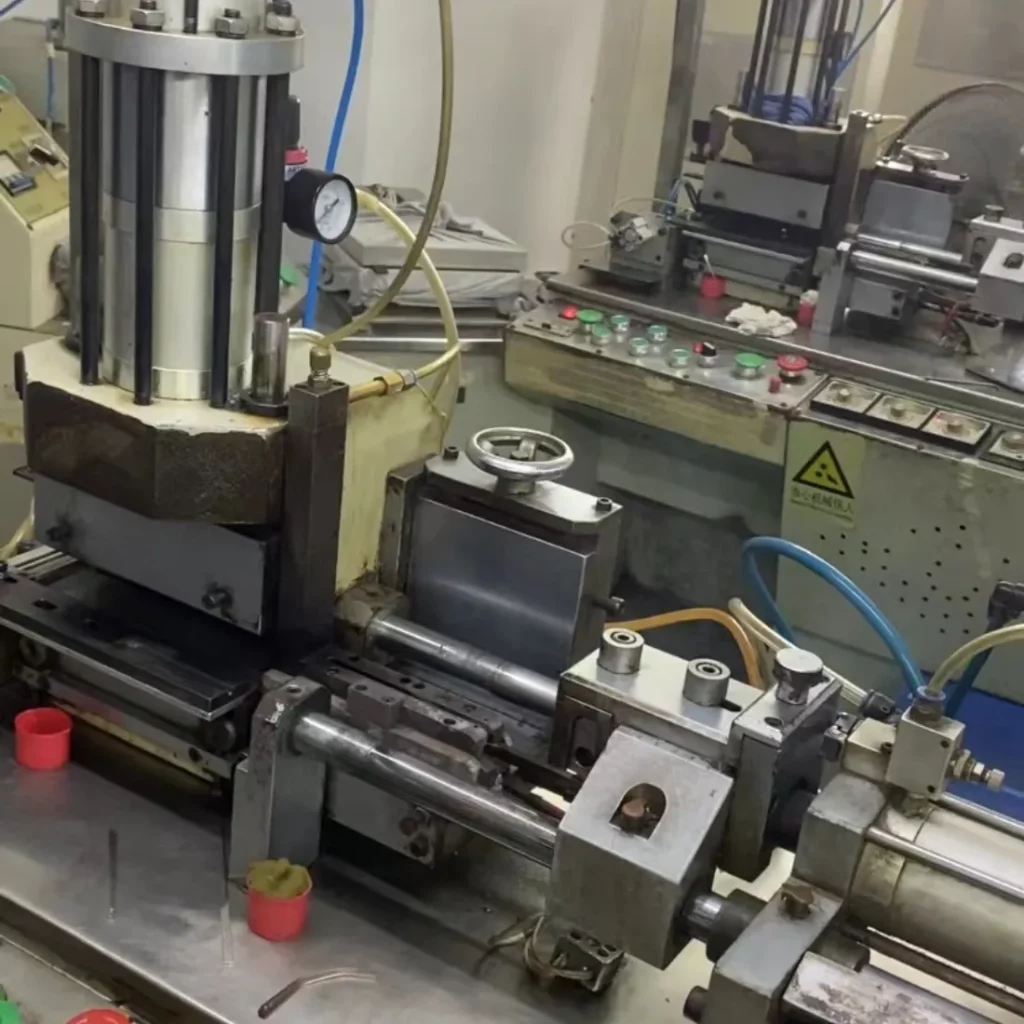

From Blueprint to Reality: A Manufacturing System Built for Complex Execution

We believe exceptional eyewear designs deserve flawless execution. That’s why we’ve built a deeply vertically integrated manufacturing platform. More than advanced machinery, it’s a complete ecosystem of lean operations, core manufacturing capabilities, and rigorous validation—engineered to deliver quantifiable precision and consistency for your most demanding designs.

The Foundation: An Efficient and Agile Operating System

Our manufacturing capability is built on an operating system rooted in Lean Manufacturing principles. This provides you with a supply chain foundation that is both stable and exceptionally responsive.

Supply Chain Intelligence & Efficiency: Strategically located in the heart of the global eyewear industry, we access a complete supply chain network—from Italian Mazzucchelli acetate to Japanese titanium—within 48 hours. We proactively monitor the status of over 50 core materials to prevent disruptions.

Strategic Production Flexibility: We support MOQs as low as 200 units per style/color, with consistent 55-day lead times from confirmation to shipment. This allows you to respond to market demands with minimal inventory risk and reliable planning cycles.

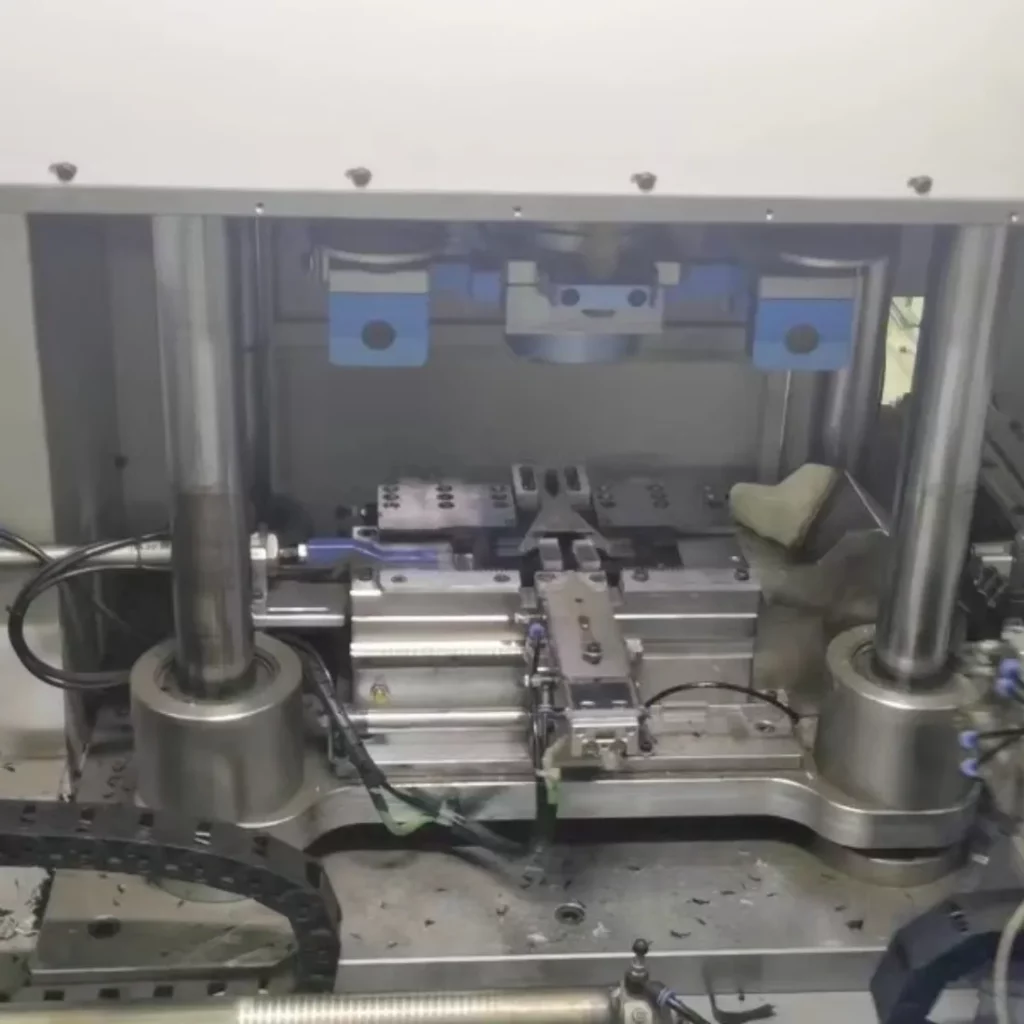

The Core: A Vertically Integrated Matrix of Capabilities

We maintain 100% in-house control over all critical production stages. This is the cornerstone of our ability to deliver superior precision and execute complex techniques consistently.

Precision Engineering & Tooling: Our matrix of 6-axis and 10-axis CNC machines from FANUC (Japan) and TRUMPF (Germany) maintains tolerances of ±0.01mm—twice as stringent as industry standard. All tooling is manufactured in-house to ±0.01mm tolerance, ensuring dimensional stability across production runs.

Advanced Materials & Artisanal Craft: We’ve mastered over 50 materials and components. Our expertise spans hand-polishing buffalo horn, welding pure titanium, laminating complex acetates, and pioneering sustainable materials like bio-based polymers and recycled ocean plastics.

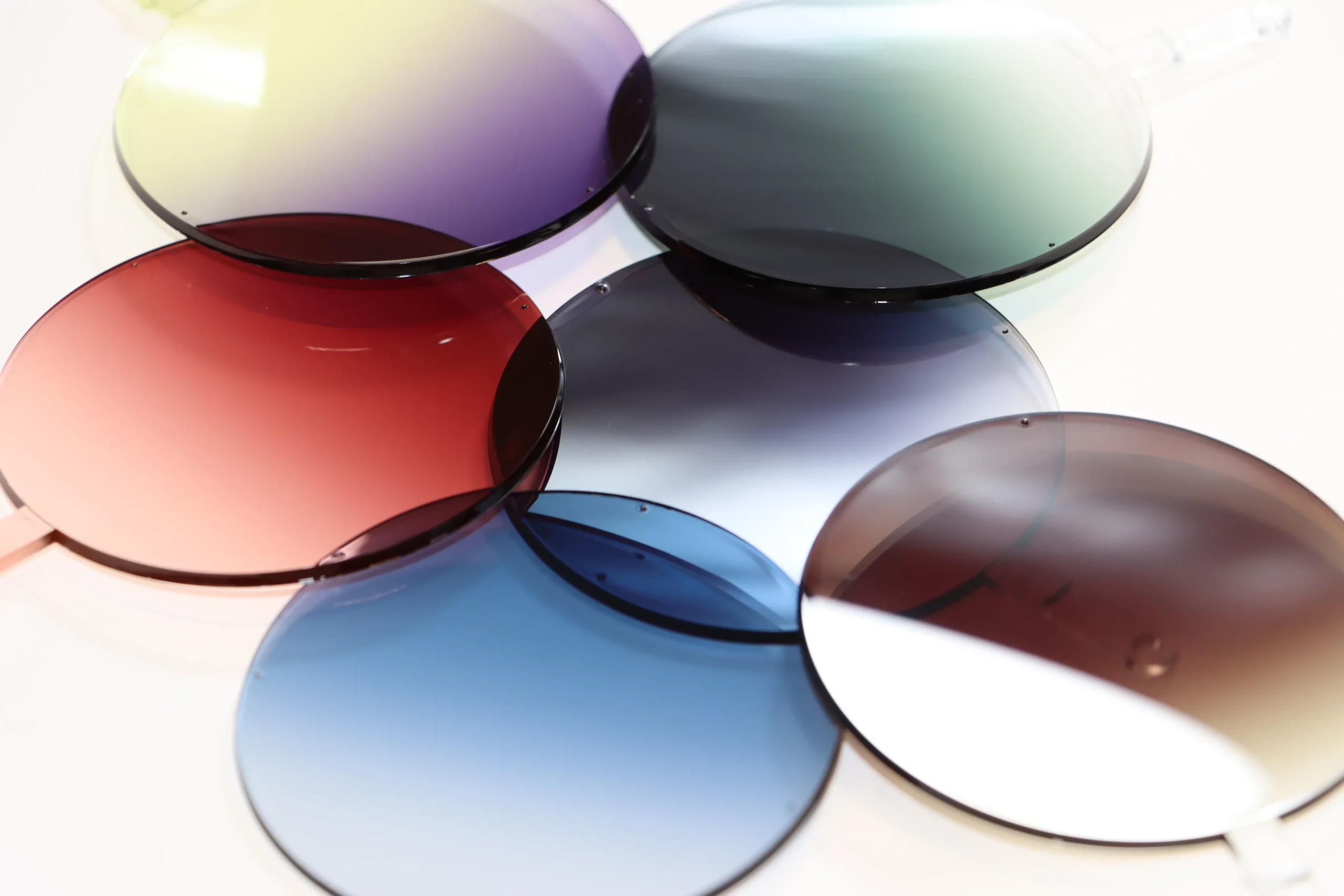

Complex Optics & Surface Treatments: Our 4 to 6-axis machinery enables stress-free lens mounting, while vacuum ion plating increases AR lens light transmission to over 98%. An additional hardening topcoat provides superior abrasion and corrosion resistance for extended product lifecycles.

The Proof: An In-House Lab That Exceeds Industry Standards

We believe true quality is defined by unwavering performance over years of daily use. To guarantee this, our in-house laboratory executes rigorous lifecycle testing to validate this performance.

Material Resilience Validation: All materials and coatings undergo environmental testing against artificial sweat, salt spray, and high-intensity UV radiation, ensuring your products maintain integrity in diverse wearing conditions.

Multi-Tiered Quality Gates: Beyond standard AQL sampling, we implement 100% inspection at 12 critical process junctures where deviations typically occur. This is followed by final sensory and balance inspection by our most experienced QC technicians, dramatically reducing warranty claims and retailer rejections.

A Disciplined Process Engineered for Zero Surprises

We understand that you are investing not just in a sunglasses, but in the certainty of a process. That’s why we’ve replaced traditional verbal assurances with a standardized workflow driven by data, systems, and experts. The following three phases demonstrate how every step of your eyewear project, from blueprint to delivery, remains under your absolute control.

Phase 1: Project Initiation & Strategic Alignment

Before any capital is committed, we partner with you to lay the groundwork for success.

Mandatory Engineering Review: Every sunglasses project begins with a comprehensive DFM (Design for Manufacturability) review, designed to proactively eliminate over 80% of potential manufacturing risks—reducing costly mid-production adjustments.

Dedicated Project Commander: You receive a dedicated Project Manager (PM) with 10+ years of industry experience who serves as your single point of contact, coordinating all internal resources to ensure seamless communication.

Standardized Project Kickoff: We provide key startup assets—such as the 3D CAD model in STEP (.step) format—within 3–5 business days. In this phase, we finalize all commercial and technical details, including custom tooling, bespoke packaging, and flexible MOQs.

Phase 2: Transparent Production & Real-time Control

Once your project moves into production, our core mission is to make the entire process transparent to you.

System-Driven Progress Tracking: You receive access to our project management portal for real-time status tracking across approximately 27 key milestones, from prototype to mass production.

Proactive Weekly Reporting: At a fixed time each week (Monday by 10 AM EST), your PM delivers a standardized weekly report containing production progress, photos from critical stages, QC checkpoint results, and alerts for any potential risks with proposed solutions.

Prompt Communication: We guarantee that all your emails and messages will receive a professional response within one business day—helping you maintain project momentum.

Phase 3: Validation, Delivery & Long-term Support

Our partnership doesn’t end when production is complete; it extends until your product is safely in your warehouse and succeeding in the market.

Verifiable Quality Results: Every shipment includes a complete QA report package. We also welcome and fully support the involvement of third-party inspection agencies like SGS or TUV at any stage.

Door-to-Door Global Logistics: Our team manages the entire logistics process, from booking freight and customs clearance to final delivery. Prior to shipment, we confirm all packing details with you via photographs and provide a variety of shipping solutions, including DDP (Delivered Duty Paid).

Structured After-Sales Support: Our relationship doesn’t end at the port. We provide a clear and efficient after-sales process to handle any potential warranty claims or future needs for spare parts.

Case Studies – Certainty You Can Measure

Real projects, audited results, and the exact controls we used to deliver quality consistency, on-time delivery, and transparent control.

European Premium Brand

Multi-Layer Acetate Consistency Across 6 SKUs

Client: Premium fashion brand with 200+ EU retail points

Product: Multi-layer acetate frames, cat-eye + rectangle, AR lenses, 18k plated hardware

Timeline: 8-week production window tied to seasonal launch

Challenge

Visible color variance triggering retailer rejections

No traceable inspection data from prior supplier

Fixed seasonal launch window

Solution

DFM² review with lamination tuning

Spectrophotometry at each gate

72-hour risk alert system

Tightened AQL with retention

Results

≤0.006% batch variance

0 retailer rejections

99.7% on-time delivery

0.01% → 0.1% scrap rate

Verification Artifacts

• Delta-E color chart progression (6-month span)

• Redacted IQC/OQC report excerpts with variance data

• 27-milestone tracker with photographic evidence

“They gave us data we could act on. No surprises—just control.“

—Brand Director, Premium Fashion

US D2C Brand

Season-Critical Drop Delivered Early

Client: Fast-growing D2C brand, direct-to-consumer focus

Product: Sport-casual hybrid frames, polarized lenses, quick-release temples

Timeline: 55-day critical path for seasonal campaign

Challenge

55-day non-negotiable timeline

Previous 3-week production slips

Marketing budget tied to exact date

Solution

ERP-prioritized production slot

48-hour material securing

Daily milestone photo updates

Pre-staged shipping containers

Results

3 days early delivery

0 major deviations

32% sell-through saved

+18% campaign ROI

Verification Artifacts

• Real-time milestone tracker with timestamps

• Risk alert email trail with mitigation actions

• Production floor photography with metadata

“First supplier to actually deliver early. Game changer for our seasonal drops.“

—Operations Director, D2C Brand

Performance sport brand

Hinge Durability in Extreme Conditions

Client: Performance sport brand, coastal and athletic markets

Product: Titanium frames, spring hinges, hydrophobic lens coating

Challenge: Premature failure in sweat/salt environments

Challenge

Hinge torque loss in coastal areas

Temple corrosion from sweat

Rising warranty claims

Solution

Hinge supplier optimization

Titanium weld parameter tuning

Salt spray validation protocol

20,000-cycle endurance testing

Results

0.07% torque degradation

0 corrosion failures

0.9% → 0.18% warranty

+23% satisfaction

Verification Artifacts

• Torque degradation curve over 20,000 cycles

• Independent salt spray test certification

• Macro photography before/after analysis

“Finally, frames that perform as hard as our athletes do.“

—Product Manager, Sport Performance

Major big-box retailer

MOQ Flexibility with SKU Explosion

Client: Major big-box retailer private label program

Product: 10 styles × 3 colors, MOQ 200 each, strict planogram dates

Complexity: 30 SKU variants with zero tolerance for delays

Challenge

30 SKU variants, low MOQs

Non-negotiable planogram dates

Zero tolerance for chargebacks

Solution

Parallel tooling setup

12 critical quality gates

Weekly EST status reports

Pre-approved packaging locks

Results

100% planogram on-time

98.6% → 99.5% yield

1.3% → 0.5% returns

9.8/10 approval rating

Verification Artifacts

• First-pass yield trending analysis

• Packaging approval timeline documentation

• OQC sampling sheets with supervisor signatures

“Only supplier to hit every planogram date. Zero headaches.“

—Category Manager, Big-Box Retail

Your Factory-Side Experts Anticipate and Solve Problems

We know that world-class eyewear requires a world-class team to harness its full potential. That is why we don’t assign you an order coordinator; we provide a dedicated, multi-disciplinary team of senior engineers, project managers, and quality specialists. They translate your designs into reliable sunglasses and act as your professional extension within our factory walls.

Your Engineering Leaders

Our technical function is led by 10+ senior engineers whose expertise is instinctive—they can foresee structural risks from a 2D drawing and recall critical tooling tolerances from memory. They are supported by a stable bench of master technicians with an average tenure of 15+ years. Their institutional know-how for exacting standards is your ultimate guarantee of consistency.

Your Project Manager

Every client is assigned a dedicated Project Manager (PM) who is more than a coordinator—they command your project. With an average of 10+ years’ industry experience, our PMs understand the market pressures you face. They align all internal resources—from engineering to logistics—and use our standardized weekly reporting to give you full visibility and control over progress.

Your Independent Quality Team

We maintain a Quality Control (QC) team of 25 specialists that operates independently from production. Our QC-to-technician ratio of over 1:8 reflects an institutional commitment to quality over volume. Their eyes are trained to detect subtle warping invisible even in high-definition photos, allowing them to identify and neutralize potential defects at the earlies

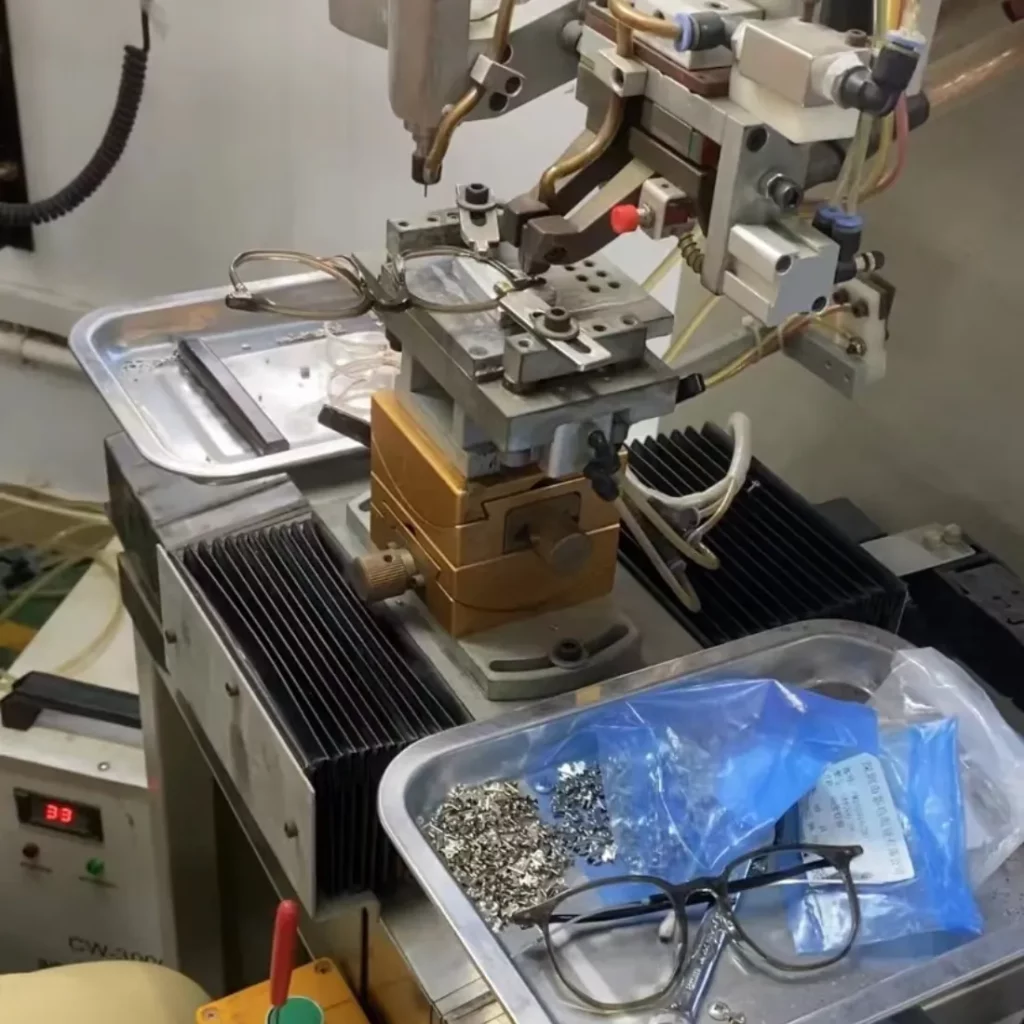

End‑to‑End Quality Assurance

Full‑line quality assurance from incoming material checks to final shipment — certified testing, inline controls and batch traceability to ensure consistent, compliant delivery for every order.

Raw Material Cutting

Shape Nose Bridge

Adding Nose Pads

Engraving Frame

Engraving Temple

Insert Needle

Shape Nose Bridge

Install Hinges

Polishing

Cutting Lens

Start Your Private-label Eyewear and Sunglasses Million-dollar Business Now!

Fully customize every detail of your eyewear and sunglasses—material, shape, color, pattern, style, and any other features you want. (You can customize everything and anything. You imagine it, we build it.)

Privacy Policy: Your information is 100% confidential. | We are an ISO 9001 & BSCI Audited eyewear manufacturing partner.

Sunglasses Manufacturing FAQ

Clear answers on certifications, MOQ, lead times, customization, quality assurance, samples, payments, logistics, delays, warranties, and compliance.

1. What certifications do your sunglasses meet?

CE (EN ISO 12312-1), FDA drop-ball compliance, verified UV400 protection. Additional market-specific certifications available on request.

2. What are your standard MOQs and color splits?

200 units per style; 100 units per color; 50 units for stock. Logo engraving is available for eyewear and sunglasses. Higher MOQs apply for new tooling or special materials.

3. What is the typical lead time?

75 days after deposit and artwork approval. Add 10–15 days for new molds/tooling or complex finishes.

4. What customization options can you provide?

Pantone colors, lens types (polarized, TAC, CR-39, nylon, PC), coatings (AR, mirror, hydrophobic/oleophobic), frame materials (acetate, TR90, metal, titanium), branding (pad print, laser, emboss), and custom packaging.

5. Do you offer private label services?

Yes. End-to-end support: design, tooling, branding, packaging, and compliance documentation.

6. How do you ensure quality?

We do incoming material checks, UV and transmittance testing, drop-ball impact tests, frame fatigue/torque, color fastness, and final AQL inspections.

7. Can we get samples and PP approvals?

Yes. Standard and pre-production samples provided. Spec sheets, test reports, and packaging proofs available upon request.

8. What payment terms and trade terms are available?

50% deposit, 50% before shipment; L/C at sight for larger orders; OA subject to credit review. Incoterms: EXW, FOB, CIF, DDP as needed.

9. Can you handle market-specific compliance and documentation?

Yes. Support for EU/US labeling (e.g., Prop 65), barcodes, HS codes, test reports, certificates of origin, and other required paperwork.

10. What happens if I encounter quality issues after delivery?

We provide comprehensive after-sales support including quality issue resolution, replacement of defective units, and continuous partnership management. Our quality warranty covers manufacturing defects, and we maintain open communication to address any concerns promptly.